Intro

Projects are my main hobby. Anybody who knows me knows that. I like original ideas, I like the challenge of figuring out how to bring things to life, I like using my hands to build things, I like the internet and putting my work out there, I like the feelings of accomplishment after I create a project that was once a sketch on paper, and I like the friends & opportunities this has brought me along the way.

I’m thankful for all the friends who sometimes help me with my projects (or are sometimes forced by me haha), although for the most part my projects have been done solo. This year I’ve started working on collaboration projects as well, and I hope to do more of those since one person can only accomplish so much.

Here’s the story of my “something” project and my first experience using Alibaba.

It seems like such a simple, easy project at first glance, but to a 23-year-old girl who had no idea what she was doing, it proved to be more challenging than I could have ever imagined. 😖

Ideas

In early 2014, for the first time in my life, I found myself with a little bit of play money. Up until that point, every project I’ve ever made cost me between $0 - $200 (usually closer to $0) and a million hours of work. This time I wanted to jump into something a bit bigger and more challenging.

I was inspired by Duncan Shotton’s brilliant product ideas to maybe try my hand at a small simple idea of my own. I sent him a few e-mails asking for some advice and it gave me enough confidence to believe that I could make my own item as well.

I had a few product ideas at this point, but none of them were good. I had to choose something that would be fairly cheap & simple for a manufacturer to make. I had some lame ideas such as an elegant, gold-filtered, flame-resistant plastic cigarette that was supposed to serve as a smoker’s “last cigarette” after quitting smoking; something to keep and remind them of why they quit. I don’t think that would have caught on. Another idea I had was to create a really giant silly band that’s the outline of a face, and it would be colourful, and when you’d wear it, you’d have to wrap it around your wrist a few times to make it look like you’re wearing a bunch of them. This wouldn’t have caught on either, because the silly bandz fad was over years ago.

Regardless of realizing these weren’t the best ideas, I tried to create some prototypes of both of these. I experimented with liquid rubber silicone and flame-resistant liquid plastics to try to create some plastic cigarettes that I could paint and test out. I failed horribly. I tried to create my own custom silly bandz by using silicone caulking and liquid rubber silicones. I failed horribly as well.

So I scrapped those ideas. 👋

Later, on my Facebook news feed, DesignTaxi posted an entry about a man named Pim De Graaff who’s selling an item named Nothing. It was literally a block of wood, painted black, and numbered. Definitely more of an art piece really, but once I saw that they were selling - and for a high price - it kind of interested me, and right away I Googled to see if someone else had made an item named something. They hadn’t.

So I decided I wanted to make something.

I chatted with some friends about which route to take for the concept. Should it just be a box with the word “something” on it and a mystery item inside? Should it be a strange abstract item that isn’t really any recognizable shape, but still technically a “something”? Should it be literal focused and only the word “something”? In the end, I decided I wanted something both literal but also directly inspired by Pim’s Nothing - white instead of black, and blocky, but in it’s own way.

I decided I wanted a chocolate-bar sized white plastic block with the word something engraved inside of it, presented in a nice little white box. Excellent choice. 👌

Design

I wanted it to be a sharp-edged block a bit larger than a chocolate bar.

I wanted the branding to be all black & white.

I found a free font that I liked called Tall, Dark & Handsome.

I found a box template generator to create a quick box layout editable in Illustrator.

I haven’t worked with 3D programs before. I decided to try Rhino. I easily made a rectangular prism, and I found out how to bring in my text path, but it actually took me hours of Googling to figure out how to cut the text out of the block. Maybe I didn’t know the proper terms to search. I also didn’t really know anyone who could have helped me. Either way, after a small mental breakdown, I did it, and maybe it was the smallest accomplishment in the world but I was proud of myself. 😊

Sample

Once I had my 3D file ready, that’s all I needed to begin getting some quotes from some manufacturers on Alibaba. Most of them simply required an .OBJ, .STL or .STP file, all of which Rhino could create I believe.

Now let me remind you that before this point, I’ve never used Alibaba. I had just months earlier learned that you could potentially get custom items made through it, and I started communicating with some manufacturers with questions. I had no idea what I was doing. And I was cool with that. 😅

I had vaguely read some bad stories about people getting scammed through the site, but I wanted to take the risk anyway.

I didn’t know anything about proper terms, the methods used to create products, the types of plastics, the going rates for items, the safest payments, etc.

I had decided I wanted to create 120 somethings, but order 10 extra to leave room for flaws.

While getting quotes, I learned about 2 methods that manufacturers were recommending to create my plastic blocks. The first was injection molding, which I was vaguely familiar with - the price per item becomes really low but the creation of the initial mold is very high. The second was CNC machining, where the bar would be cut and then & drilled/etched using a machine; each item would cost more but there would be no molding fee. The majority of the quotes I received were between $1,500 - $5000.

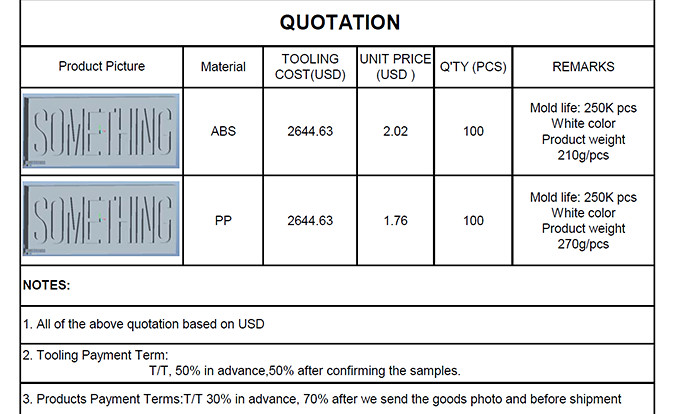

One of the higher quotes I received.

The high mold fees scared me - I wasn’t used to seeing such high numbers, so I started focusing on getting CNC quotes only. The quotes were still pretty high! After many quotes, I settled for the cheapest one (see price chart below which includes shipping etc.) and ordered a sample that cost me about $120.

A couple weeks later I received it.

It was smooth.

It was a really nice off-white colour with just the right amount of opacity.

It was perfect. 😍

That was easy, I thought.

Boxes

Once I got my sample, I fitted my box template to perfectly fit that size. Once I had the .ai file ready, I could start e-mailing companies for some quotes. I wanted 140 boxes just to be safe.

I’ve never had boxes made before. I didn’t know how thick I wanted the cardstock to be, or what the proper terms were. I had no idea what I was doing. And I was cool with that. 😅

I got some crazy high quotes! Many ranging between $400 - $2,000, and of course, most of them rejecting such a low quantity to begin with.

A box quote that I received.

The cheapest quote I found was from Captain Printworks - just over $300. They were super nice and sat down with me at their computers, fixed up my template to make the flaps lock, and printed off a quick sample to show me. After that, I ordered.

I wanted to print a secret message inside the boxes. To save money on that, since I’d have to print on the other side of the box, I decided to instead order a stamp from Vistaprint and manually stamp each one myself.

I also decided I’m going to fold & tape all the boxes myself, once again, to save money.

Captain Printworks gave me a free roll of special tape to start me off. I’ve never heard of this tape before. It’s a special double-sided tape called ATG tape. Folding boxes takes a lot of time - and the tape is quite permanent. If you make a mistake, you can’t really unstick it.

Once the unassembled boxes were ready, I went to pick them up along with the die used to create them (which I get to keep and can reuse in the future for cheaper boxes if I wanted to).

The die and some unassembled boxes it created.

I got my Vistaprint stamp and started stamping the message on the inside. I didn’t realize that the ink in the stamp would take an eternity to dry. Literally days! 😕 I was living with my parents in a tiny little room that could only fit a single bed & desk. I had to figure out a way to stack all my stamped boxes so that they wouldn’t touch one another, and let them sit for a week to dry, so I used Jenga pieces and stacked away!

Although I hadn’t gotten my somethings yet, I started to assemble & tape some boxes to get a head start. It took me a while to figure out a good system for this - I had to figure out which flaps should be closed first.

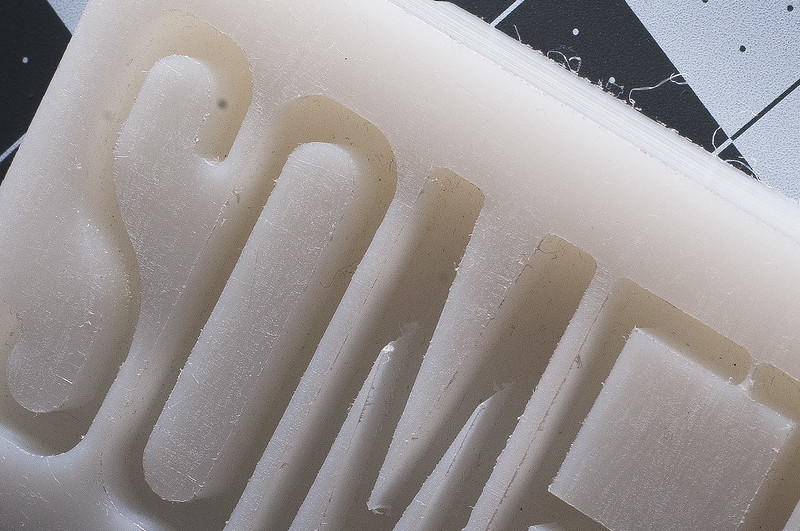

A short clip of a "Something" being made at the manufacturer's, before being cut to size and then each one is hand finished by me.

Posted by Dorota Pankowska (Dori the Giant) on Monday, May 12, 2014

Production, Problems, Problems, & Problems

After I received the sample that I was happy with, I decided to order the full run. I didn’t know anything about contracts, or any way to ensure the quality of the product. I didn’t know much about payment types, but I was familiar with Paypal. I knew Paypal has purchase protection meaning they could refund your money if something went wrong. This made me more confident to pay for my purchase, although I later found after reading more about purchase protection, that you’re not protected in the case of custom made items.

They gave me an estimated completion date of 1 month. The person from the company I was communicating with was a young guy who didn’t speak English well. A lot of miscommunication happened (which is the case with almost every Alibaba communication I have ever made since then as well). I wasn’t even sure of his age - I think he told me he was 23, and then later told me he’s actually 21 in “Western” years. What? 😂

After ordering & starting the project, they told me they’re going to change the plastic colour a little bit. They didn’t ask me, they just told me. I wasn’t happy. 😠

The production ended up taking longer than they estimated.

To prevent my parents from having a heart attack and questioning why a huge package from China was at their door, I told the manufacturer to ship it to my friend’s Creative Group instead. Thanks Daniel! (I eventually smuggled them into my house.)

Once they arrived, I had to pay over $60 in customs fees.

Sweet, my items are here! Hold up... 😥

Remember how I mentioned that I got a head start assembling boxes? Well...

1.

The plastic bars were 2mm thicker than the sample, which was what I used to create the boxes, half of which I had already assembled. So they didn’t fit in the boxes, and if I fit one in, it was almost impossible to take out.

2.

The bars weren’t perfectly straight and level like the sample was. There was a slight curve on each and every single one.

3.

Not only was the plastic more white, it was also more transparent and more soft and prone to scratches.

4.

They were not finished. They were not sanded or buffed or polished or anything. They literally just came out of the machine and had scratches and tiny little pieces of plastic feathering out from every corner and edge inside the letters.

5.

Although I ordered 10 extra blocks in case there were flaws, over 10 of them ended up having flaws, often big holes or extremely deep scratches.

6.

Two were missing. This was a complete disaster 😣😭 - but it could have been worse.

Comparing the sample to the bars I received.

Alright, so I had to problem solve now to try to salvage this project as much as I could. I don’t give up that easily.

Firstly, I complained to the manufacturer about the problems. I knew that since I didn’t really sign any papers and most of my communications were through Skype chat, I wasn’t in a position of power. But I tried anyway, and I threatened to get a Paypal refund via purchase protection (even though like I mentioned above, it turns out I probably wouldn’t have been able to do that after all). They agreed to refund me $200 USD. That was better than nothing.

Moving on, instead of remaking the boxes, I opted to find a way to cut the 2mm off of each block. This would ensure they fit in the boxes, and it would also make the back perfectly straight so that they can at least sit flat on a surface. After doing some googling on table saws & blades, I found that you can get special plastic-cutting blades that don’t get as hot and don’t melt plastic like regular wood blades probably would. I bought one for $100, and found a friend with a table saw who was willing to cut them all for me. It was such a hassle, the plastic chips were everywhere, and I think it took 2 sessions - but we succeeded. Thanks for helping, Alex!

Next up was hand-finishing. This was the most annoying part. 😑 At first I tried using my sister’s hand-operated sander, but it only made things worse. I later tried using a Dremel to clean up the insides, but it would also make things worse. The best option was literally just buying a few different types of sand papers and sanding each block one by one with my hands. Sometimes I’d use a wooden block to wrap the sand paper around, and sometimes I’d use little objects to get inside the crevices of the letters. Sometimes I would spend over 30 minutes sanding just one of them and still wasn’t satisfied with the result.

Detail shot of how the product arrived.

I still haven’t hand-finished all of them. I stopped about half way through to prevent myself from going insane, and the rest I’ll finish later, or as they get sold.

After hand-finishing, I was happy enough with the way the somethings looked. 👍

Stickers

Website, stickers, shipping, & more

Fortunately I’m a little bit HTML/CSS savvy. I bought the domain asomething.com for about $12 CAD. I found a template close to what I wanted and customized it.

I ordered circle stickers from StickerYou for $30 USD. When they arrived, they weren’t perfectly centered so I e-mailed them about it and they sent out more - but they weren’t perfect either. I’ve realized that almost anywhere I’ve ever ordered stickers, the printers always have issues perfectly aligning the content.

I also ordered some regular stickers that said “something” on them from Vistaprint for $25.

For thank you cards, I decided to get some pretty foil-stamped business cards from Vistaprint for $40. I left one side blank for writing a personal note.

I decided to go with Canada Post for shipping. I had to figure out some prices and use an average for people buying a something online, since I wasn’t using an eCommerce system. I was using Paypal buttons. I also sold them on Amazon for a while, which had many more fees and required me to put even higher shipping prices on there. I had to buy a $9 UPC bar code to list my item on there, as well as open a seller account, which I have now closed.

Breakdown of costs

Here are the approximate costs of the entire project. I had to do some digging for some receipts/invoices, and some don’t specify CAD or USD, so it’s not entirely precise:

| Somethings: | $1310 |

| Boxes: | $273 |

| Sample: | $100 |

| Plastic cutting blade: | $100 |

| Total customs fees: | $80 |

| Amazon seller fees | $60+ |

| Thank you cards: | $40 |

| Circle Stickers: | $30 |

| Something Stickers: | $25 |

| Domain: | $10 |

| UPC Barcode: | $9 |

| Partial refund: | +$200 |

| Total: | USD $1,837 CAD $2,094 |

Time spent conceptualizing, designing, googling, e-mailing, photographing, cutting plastic, sanding plastic, folding boxes, buying supplies & much more: only a million hours, NBD. 😏

I decided to price the somethings at CAD $20, and if they all do sell, I'd be making CAD $2,400. Considering I gave some out as gifts, my best chance is simply making the money back, which is fine with me. I went into the project to get a learning experience and create an idea in my head, not to make a lot of profit - although I'm aiming for more profitable projects in the future.

Press

I didn’t do any intensive marketing for this project. I submitted it to a couple places. I wanted the project to challenge me to learn more about marketing, but I didn’t want to rush and sell the items fast. Once they’re sold out, they’re gone forever, and I don’t think I want that yet.

A couple of places that wrote about it:

BlogTO: I got a little entry on here about the project, and every single commenter was extremely rude & negative. I’m not even kidding. That’s Toronto for you.

Brampton Guardian: Since I launched this project right before moving to Toronto, it was my last official project as a Brampton artist and I got a little article about it in the paper.

I got some mentions from a few small websites here and there, which sometimes led to strange random sales (one person bought 6 at once!). When I met my friend Michael Stevens in Toronto, I gave him a something as a gift, and he posted it on social media - I sold over 13 that week.

Outcome, Reflection & Advice

To this day, I’ve sold about half of the somethings. I number & sign each one on the back, and I keep track of every number in a chart.

Not one person found my secret message hidden inside the box (or at least no one brought it to my attention that they found it).

Some advice for anybody who wants to start their first project with Alibaba:

Be careful. I took a risk and it could have ended up in me being completely scammed for all of my money - if you do some googling on Alibaba scams, and especially read the comments on those pages, you'll come across plenty of people who have been scammed for thousands of dollars. I was lucky and unlucky at the same time. I have since learned that manufacturers on Alibaba are notorious for sending out perfect samples to attract customers, and then sending them terrible products afterwards.

Here is a good article on preventing Alibaba scams.

I’ve used Alibaba a few times since this project. The miscommunication can be hard to deal with since many of them don’t speak English very well, but you have to be patient.

If you have money, you can look into quality assurance services in China where someone can visit your manufacturer to inspect products & more. You can also look into Alibaba’s Trade Assurance feature.

Looking back at the cost of my project, I believe I should have stuck to injection molding after all. I felt I would be saving money on CNC Machining since I only wanted to order 130 pcs, but I ended up with more expenses and an unfinished product. If I spent more time getting injection molding quotes, I could have probably had the project done quicker, cheaper, and with no hand-finishing involved.

Thanks for reading - feel free to leave a comment if you have any questions!

And feel free to buy something. ;)

I think that its awesome that you posted this. I am working my way through the article still but it is a great example of you getting a simple product to be made ... and I needed exactly that.

ReplyDeletegreat post I started my journey at alibaba.com and learnt a similar lesson to you but got there in the end. www.musclefitbasics.com

ReplyDeleteThis is awesome. Thanks for sharing! I am working my way through orders on Alibaba right now.

ReplyDeleteWhat were the other projects you used Alibaba for?

ReplyDeleteIf you go to my website, dorotapankowska.com, you'll see a necklace & a coin project as well. I've made lapel pins as well from China but the manufacturer was recommended by a friend. Also, I'm still working on another Alibaba project - which was more of a hassle than this!

DeleteFinished reading the post. Great and thank you. How many suppliers did you ask for quotes and how many gave you quotes? Did you do it all through email (in English)? How will you control quality in the future?

ReplyDeleteThank you,

George

I probably asked about 20 for quotes since not all of them reply. I probably got about 10 replies. I do everything in English - it can be so hard to communicate and you have to be patient and sometimes think twice about what the person is trying to tell you.

DeleteAlthough controlling quality can be hard on low-budget projects, one lesson I've learned is to double-check every single step and keep asking for follow-ups, photos, etc. Sometimes when they answer "yes", it turns out they didn't actually understand you after all. Make sure to ask many different questions to get confirmation for something you're trying to do.

It looked so simple... Thanks for the glimpse behind the scenes, very interesting! And good luck with finishing the other half, it seems like a hell of a job indeed.

ReplyDeleteHaha thanks!

DeleteThis comment has been removed by the author.

ReplyDeleteHi there. I am interested in ordering products from Alibaba as well. Could you tell me which company you used for shipping the products from China?

ReplyDeleteHey Kalian. Do you mean shipping company like FedEx or UPS? When I order products from a manufacturer, they usually already have shipping companies that they use. It's usually DSL or FedEx from my experience, although sometimes it's been some Chinese posts that I've never heard of. As long as there's tracking I've never really cared about the company too much.

DeleteBe careful though - there are so many times where I got charged customs fees I didn't know about. Always ask the manufacturer about this beforehand!

Nice blog, nice sharing...

ReplyDeleteReally true ! communication is the real problem when produce something from china..

how can things go well if they can't even understand 100% what we want.

next month i'll study abroad in china for 1 years, I hope I can get a cool idea like yours so then i can produce directly to avoid misscomunication. Currently still no idea what to produce/bulk buy..

goodluck for your future¤t project..

I would love to see what you do. Feel free to share with me if you'd want to compare experiences later!

Delete